Guide: Your path to the optimum special machine

In a constantly evolving industrial landscape, individuality is becoming increasingly important. Special-purpose machines offer this customized solution. Here you can find out in detail what characterizes special machine construction, why it can be essential for your production and how you can optimally design the process from planning to implementation.

1 Why special machines?

1.1 Customized solution

Standard machines are often limited in their functionality. Special machines, on the other hand, are developed exactly according to your needs and optimize your processes with pinpoint accuracy.

1.2 Increased efficiency

They enable a faster, more precise and often more cost-effective production process, which leads to a considerable increase in your production efficiency.

1.3 Technological edge

With special machines, you can use innovative technologies and production processes that give you a clear advantage over your competitors.

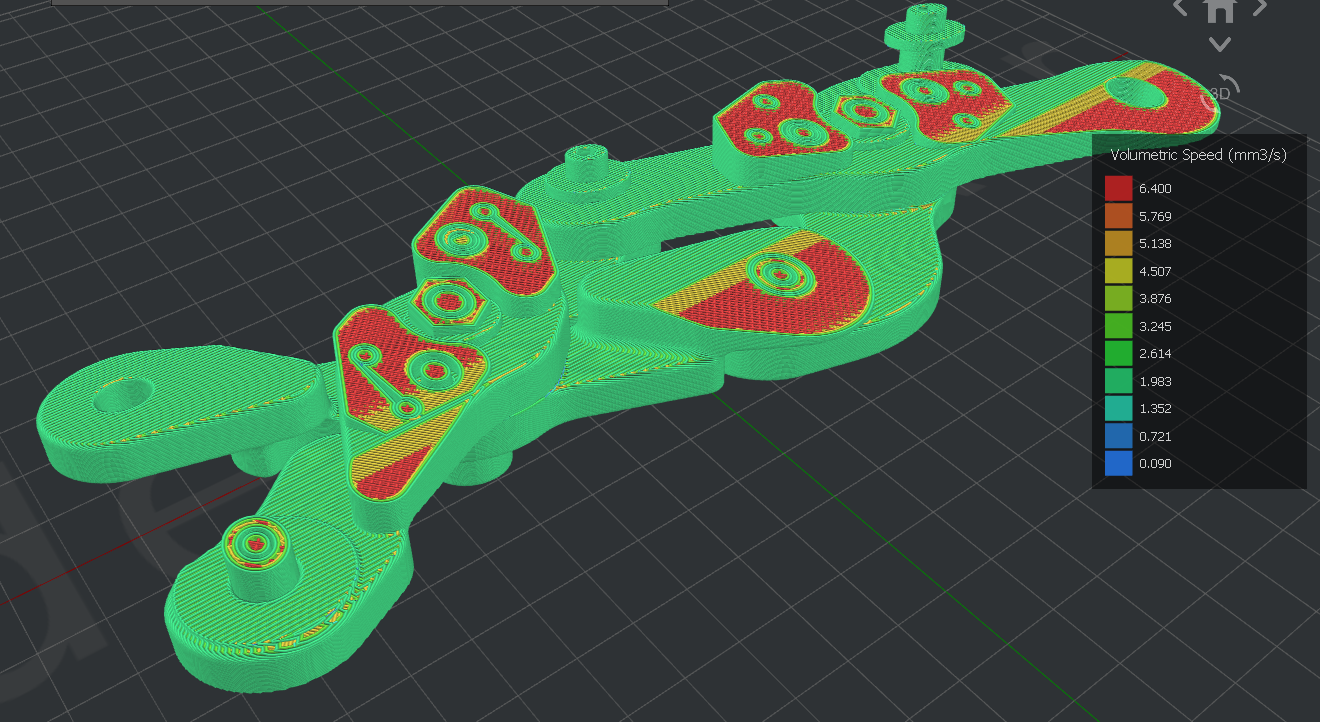

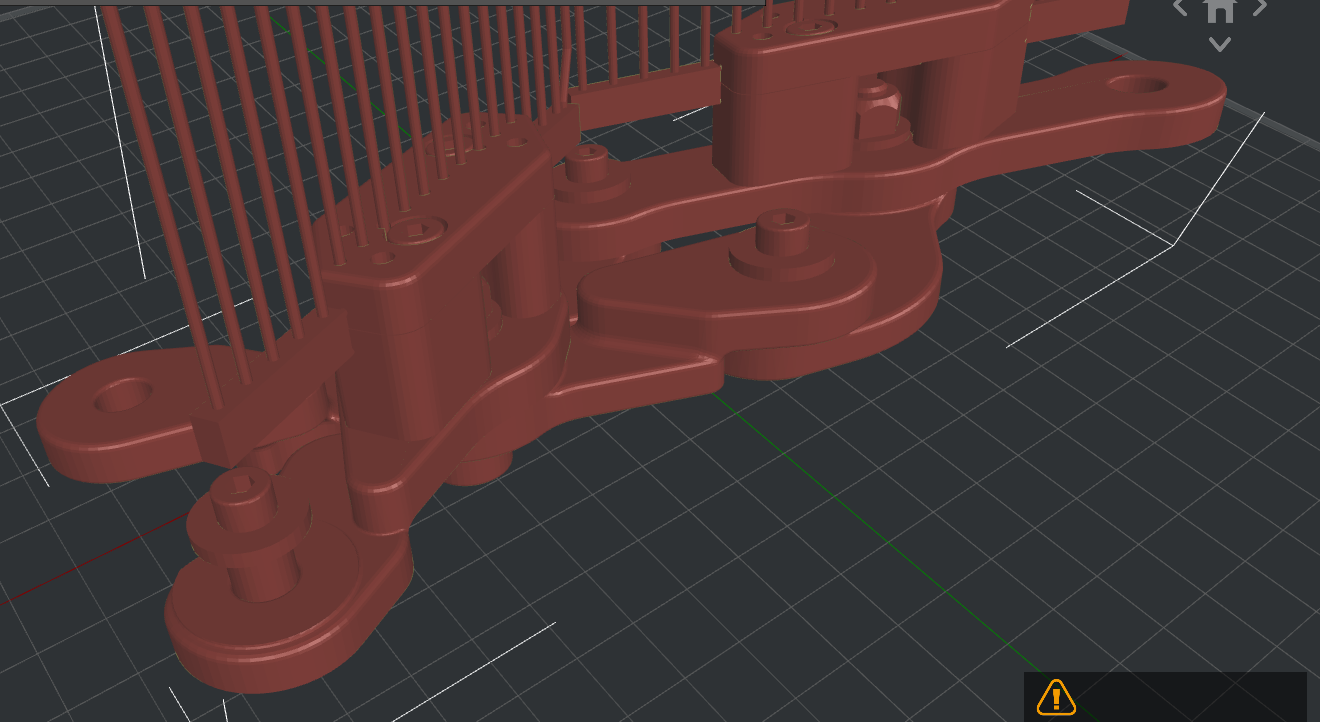

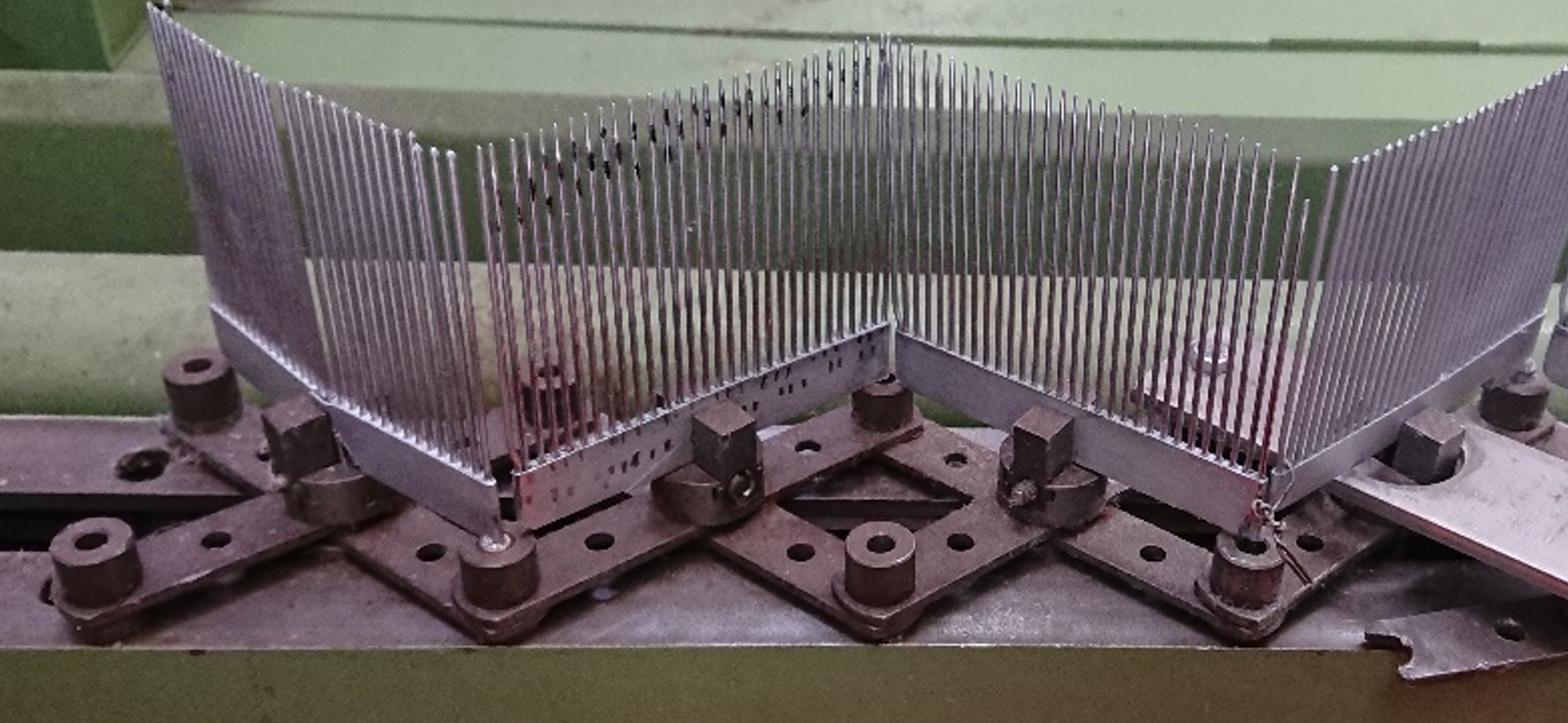

3D model of the D³-adjustable weaving comb (before & after)

2. planning and analysis

2.1 Requirements analysis

Before you decide on a special machine, you should know exactly what requirements it must fulfill. Which materials should it process? What are the expected quantities?

2.2 Technical requirements

Take into account technical standards, interfaces to other machines and, if necessary, legal requirements or certifications.

2.3 Cost-benefit analysis

Consider how quickly the investment in a special machine could pay for itself through productivity increases and cost reductions.

D³-adjustable weaving comb with new 3D printing parts

3 Selecting the right partner

3.1 Expertise

The manufacturer should have proven experience in implementing projects that meet your requirements.

3.2 Communication

Cooperation is based on communication. A good partner should always have an open ear for your wishes and concerns.

3.3 Transparent development process

A transparent development process enables you to make corrections at an early stage and thus ensure that the end result meets your expectations.

4 Implementation

4.1 Design and construction

Detailed plans and models are created that cover all technical aspects of your machine.

4.2 Prototyping

A prototype enables a realistic check of functionality before actual production begins.

4.3 Final assembly and testing

After production, all components are assembled and the machine is subjected to a series of tests to ensure that it works flawlessly.

5. Maintenance and support

5.1 Introduction and training

A competent partner offers not only an introduction to the machine, but also ongoing training for your team.

5.2 Service and repair

Make sure that the manufacturer also offers reliable service after installation and quick repairs if necessary.

5.3 Updates and modernization

A good special machine is future-proof and can be brought up to the latest technological standards if required.

Conclusion

Special machines offer you the opportunity to optimize your production processes. With the right preparation, a competent partner at your side and regular maintenance, you will benefit from the advantages of your customized machine for many years to come.

D3-Solutions is at your side as an experienced partner in special machine construction. Contact us to find out how we can revolutionize your production processes together.